Polished Concrete

by Professionals

Polished Concrete Services From Horsley Specialties

When it’s time to restore your concrete flooring, you can count on top-quality service from Horsley Specialties. Our team of professionals is trained in the latest concrete polishing techniques and uses state-of-the-art equipment to deliver a smooth, durable, and glossy finish every time.

Additionally, we can provide an expert concrete assessment to identify and address any issues right away, leaving your floors looking refreshed and polished to perfection.

Polished Concrete Floors Create a Welcoming Space For Your Customers

We Restore And Renew Your Concrete Floors

Achieving a beautifully polished concrete floor is a meticulous process, and we approach it with the attention it deserves. Properly polished floors not only enhance your space but also ensure durability and long-lasting performance.

Our concrete polishing services go beyond aesthetics. Our process includes grinding away uneven or wavy floors, eliminating unsightly or dangerous imperfections to create a sleek, uniform & safe surface. Using advanced concrete polishing equipment, our expert team can tackle tough imperfections, grind down large humps or cracks, and remove old coatings or materials, leaving your floors flawless and ready to impress.

Proudly Providing Polished Concrete Services Across

The Midwest

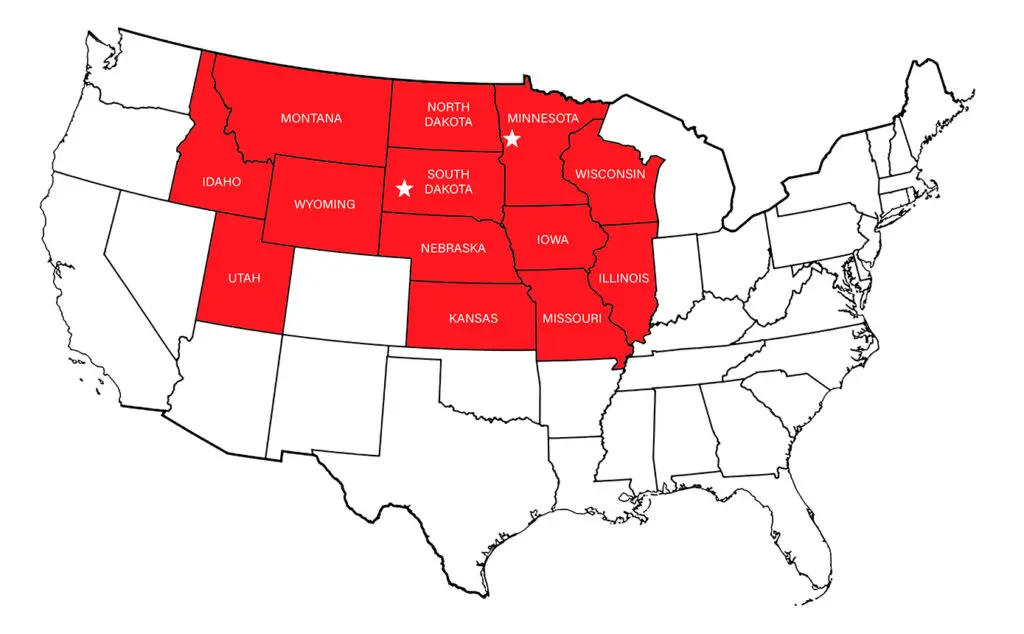

Horsley Specialties Inc. has two physical offices, one in Rapid City, South Dakota, and another in Moorehead, Minnesota. We are currently licensed to serve the following states: South Dakota, Minnesota, North Dakota, Montana, Idaho, Utah, Wyoming, Nebraska, Kansas, Missouri, Iowa, Illinois, and Wisconsin.

- South Dakota

- Minnesota

- North Dakota

- Montana

- Idaho

- Utah

- Wyoming

- Nebraska

- Kansas

- Missouri

- Iowa

- Illinois

- Wisconsin

Concrete Solutions for Every Industry

Inudstrial Facilities

Event Venues

Retail Stores

Corporate Offices

Polished Concrete FAQ

Polished concrete is a durable, low-maintenance, and eco-friendly flooring finish achieved by grinding and polishing a concrete surface with diamond abrasives.

Benefits include increased durability, improved slip resistance, removes old coatings and glues, enhanced aesthetics, and reduced maintenance costs.

While the polishing process can be noisy, We use electric and propane-powered equipment. Electric is substantially quieter but does take longer to complete a project.

How long the process takes depends on several factors: size of the area, configuration of the area, obstructions or immovable items in the area, starting condition of the floor, number of floor repairs required, and the desired finished product.

The area should be clear of obstructions and debris. Any removable items should be cleared from the grinding area.

The work area will need to be unoccupied to facilitate an on-time completion, the rest of the facility may still be occupied.

New concrete needs 30 days to cure before it can be polished.

While we do apply a seal coat at the end of polishing to protect from scratches and staining, we do not apply any surface coatings that alter the finished surface in color or appearance.

NO traffic is allowed on the floor for one hour after densifying or sealing. Foot traffic is acceptable after 1 hour, moderate traffic after 12 hours and full use after 7 days.

All concrete can be ground and polished with varying outcomes depending on the make-up and application.

Yes, you can choose from a matte to a high-gloss finish. However, higher levels of gloss may introduce a slipping hazard.

Regular sweeping and mopping are sufficient for most maintenance. Periodic sealing is required to maintain protection. Periodic use of a rejuvenating cleanser/sealant is recommended to prolong the life of the shine.

Yes, we offer free estimates to assess your specific needs and provide a tailored quote. Get in touch with our team today to get started!